Archive: Apr 2021

Applications of Aluminum 5086

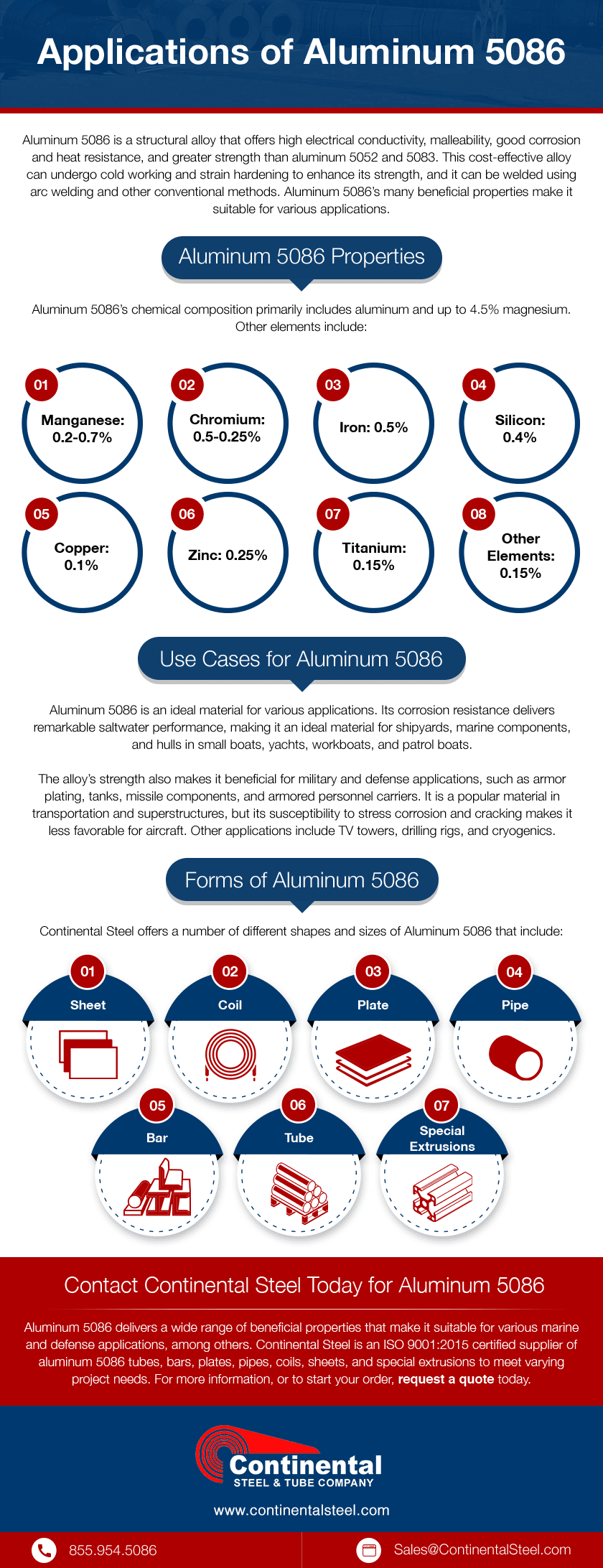

Leave a CommentAluminum 5086 is a structural alloy that offers high electrical conductivity, malleability, good corrosion and heat resistance, and greater strength than aluminum 5052 and 5083. This cost-effective alloy can undergo cold working and strain hardening to enhance its strength, and it can be welded using arc welding and other conventional methods. Aluminum 5086’s many beneficial properties make it suitable for various applications.

Aluminum 5086 Properties

Aluminum 5086’s chemical composition primarily includes aluminum and up to 4.5% magnesium. Other elements include:

- Manganese: 0.2-0.7%

- Chromium: 0.5-0.25%

- Iron: 0.5%

- Silicon: 0.4%

- Copper: 0.1%

- Zinc: 0.25%

- Titanium: 0.15%

- Other elements: 0.15%

The alloy has a tensile strength measuring between 275 and 350 MPa, with its highest tensile strength being achievable in cryogenic conditions. Its elongation is 12%, and its minimum stress-proof is 125 MPa. Aluminum 5086 can meet a wide range of regulations and industry standards, including MIL, SAE, ASTM, UNS, and QQ.

Use Cases for Aluminum 5086

Aluminum 5086 is an ideal material for various applications. Its corrosion resistance delivers remarkable saltwater performance, making it an ideal material for shipyards, marine components, and hulls in small boats, yachts, workboats, and patrol boats.

The alloy’s strength also makes it beneficial for military and defense applications, such as armor plating, tanks, missile components, and armored personnel carriers. It is a popular material in transportation and superstructures, but its susceptibility to stress corrosion and cracking makes it less favorable for aircraft. Other applications include TV towers, drilling rigs, and cryogenics.

Forms of Aluminum 5086

Continental Steel offers a number of different shapes and sizes of Aluminum 5086 that include:

- Sheet

- Coil

- Plate

- Pipe

- Bar

- Tube

- Special extrusions

Contact Continental Steel Today for Aluminum 5086

Aluminum 5086 delivers a wide range of beneficial properties that make it suitable for various marine and defense applications, among others. Continental Steel is an ISO 9001:2015 certified supplier of aluminum 5086 tubes, bars, plates, pipes, coils, sheets, and special extrusions to meet varying project needs. For more information, or to start your order, request a quote today.

Nickel 625 a Superalloy for Extreme Environments

Leave a CommentNickel 625, commonly referred to as Inconel 625, is a superalloy that can be used in extreme applications and environments like those in the aerospace and marine industries.

This austenitic alloy has exceptional resistance to oxidation, corrosion, and fatigue, and it has excellent toughness and strength at extreme temperatures. Nickel 625 derives its strength and corrosion resistance from its molybdenum and columbium content, making it suitable for a variety of oxidizing and non-oxidizing environments.

Features of Nickel Alloy 625

Nickel 625 possesses a unique combination of features that makes it ideal for extreme environments. These features include:

Resistance to Chloride Pitting

Chloride pitting is a type of pitting corrosion that can degrade metals through small weak points. If the external surface layer of an oxidized or treated material is scratched or the underlying material is otherwise exposed, pitting can occur. Nickel 625 is resistant to this form of corrosion.

Resistance to Crevice Corrosion Cracking

Components constructed from nickel 625 are resistant to crevice corrosion. This type of corrosion is caused in stagnant fluids like seawater, which can penetrate small cracks and pits to create a high-pH environment that degrades the metal.

Immunity to Chloride Ion Stress Corrosion Cracking

When tensile stress and corrosive chloride ions combine, they can cause cracks to appear in impacted metal surfaces. Nickel 625 contains enough nickel to resist this form of corrosion, making it a superior choice to stainless steel.

Resistance to Caustic Materials

Nickel 625’s high nickel content protects it from damage in alkaline solutions and exposure to hydrogen ions.

Resistance to Flowing and Stagnant Seawater Damage

Because of its unique resistance to pitting and other forms of corrosion, nickel 625 can withstand seawater moving at different speeds without the risk of wearing away or degrading the surface of the metal.

Using Nickel 625 in the Aerospace Industry

Due to its strength and resistance to damage in extreme environments, Inconel 625 is an excellent material for fabricating aerospace parts, equipment, and hardware. Applications include:

● Aerospace Turbines. Nickel 625 has superior strength and creep resistance. This protects turbines from deformations caused by the high temperatures generated during turbine operation.

● Turbine Shroud Rings. Turbine inlet nozzles are set in inner and outer shrouds. Inconel 625 shroud rings provide protection from thermal stress, add strength to support the shrouds and vanes, and accommodate movement from thermal expansion.

● Engine Thrust-Reverser Systems. These safety systems assist jets in slowing down after touchdown to protect the brakes and give jets more flexible landing distances. Inconel 625 components can withstand the stress and forces of this operation.

● Jet Engine Exhaust Systems. Exhaust systems manage the flow of hot exhaust gases so they don’t interfere with the jet’s performance. Components made from nickel 625 ensure that the systems can withstand extreme temperatures from gases and heat radiation.

● Aircraft Ducting Systems. Aircraft ducting systems are high-pressure systems that include functionalities like anti-icing, engine bleed air, and more. Inconel parts can resist damage from both extreme heat and extreme cold for reliable performance.

Contact Continental Steel & Tube Today for Nickel 625

At Continental Steel & Tube, we specialize in supplying high-quality nickels, steels, and other metals. As a proud supplier to some of the biggest names in the aerospace and military industries, we ensure that our partners have the necessary metals and alloys to meet strict project specifications and requirements.

We have different forms of options:

- Sheet (ASTM B443 ASME SB443 AMS 5599)

- Plate (ASTM B443 ASME SB443 AMS 5599)

- Bar (ASTM B446 ASME SB446 AMS 5666) / (AMS 5666, ASTM-B-446, ASME-SB-446)

- Pipe & Tube (welded & seamless) (ASTM B444 / ASTM B704 AMS 5581 )

- Wire (AMS 5837)

- Fittings & Flanges (ASTM B366 )

For more information, or to get started on your order, request a quote today.