Aluminum

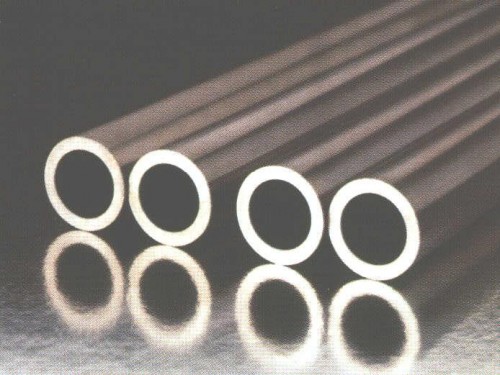

Aluminum Tubing

As an ISO 9001:2015 registered company and industry-leading supplier of quality metals, Continental Steel & Tube Company understand the importance of aluminum—i.e., its benefits and use—to the industrial sector. Due to its versatility and desirable properties, aluminum finds application in a wide range of industries, including aerospace, construction, general manufacturing, medical, and transportation.

At Continental Steel & Tube, we offer aluminum in a variety of grades, forms, and sizes to suit virtually any application. Regardless of your project requirements, chances are you’ll find the aluminum form you need in our facilities.

How Aluminum Is Manufactured

The aluminum manufacturing process implements two operations:

- The Bayer process extracts aluminum oxide from bauxite, an ore containing aluminum oxide and other metal compounds. Once extracted, the aluminum oxide is left to crystallize and then heated to form pure aluminum oxide.

- The Hall-Héroult process further refines crystallized aluminum oxide by dissolving the compound into an electrolyte solution and employing a direct current to initiate a chemical reaction that separates the aluminum atoms from the oxygen atoms. The resulting molten aluminum boasts 99.8% purity and can be worked into the final form for further processing.

Although aluminum demonstrates exceptional material strength on its own, during the manufacturing process, alloys are often added to enhance its strength further. In addition to its strength, aluminum is also known for its durability and energy absorption properties during impacts. Additionally, compared to steel, it exhibits a better strength-to-weight ratio that allows for the fabrication of strong and lightweight parts.

At Continental Steel and Tube Company, we offer aluminum tubing in 5083, 5086, 2024 and many additional grades. Whether your application calls for drawn, rectangular, round, or square tubing, our inventory has what you need to get the job done.

When to Use Aluminum Tubing

Aluminum is employed in a number of notable industries for both routine and specialty applications, such as:

- Aerospace and Automobile. Aerospace and automotive manufacturers use aluminum tubing as fuselage, hydraulic system, and fuel line components.

- Construction. Aluminum material finds applications in a broad range of construction applications, such as in the roofing, siding, door and window frames, and curtain walls of buildings.

- HVAC and Refrigeration. Aluminum tubing plays a central role in many HVAC and refrigeration systems due to its excellent thermal conductivity properties.

- Marine. Aluminum tubes are used to construct marine equipment, such as shark cages, as the metal demonstrates greater buoyancy and saltwater corrosion resistance than other construction materials.

- Medical. Medical tool and equipment manufacturers regularly use aluminum tubes to construct products such as bed frames, collapsible stretchers, and wheelchair frames.

- Recreation. Recreational equipment manufacturers use aluminum tubing to create equipment such as camp chairs, tables, and tent poles.

Benefits of Aluminum Tubing

Aluminum presents manufacturers and end-users with several benefits over other materials, including

- Strong, but lightweight construction. Aluminum demonstrates an excellent strength-to-weight ratio. Aluminum and aluminum alloys can exhibit strength equal to steel with one-third of the weight.

- Durability. Aluminum material exhibits resistance to various environmental factors, including corrosive substances and UV radiation. This quality ensures a longer service life of aluminum products.

- Flexibility and ease of fabrication. As aluminum is available in a variety of alloys with varying properties, it can be worked by several different manufacturing processes—including rolling, extrusion, forging, casting, etc.—for virtually any application.

- Non-combustible. While aluminum does melt at around 600 degrees Fahrenheit, it does not burn or release potentially harmful gases.

- Thermally and electrically conductive. Aluminum offers high electrical and thermal conductivity properties, enabling it to be used in electrical and thermal transfer applications.

- Recyclability. Aluminum is highly recyclable, allowing manufacturers to use and reuse materials for construction applications.

Aluminum tubing, in particular, affords manufacturers and end-users several advantages, such as a superb strength-to-weight ratio and excellent compression and support characteristics. Additionally, the square shape contributes to uniformity throughout the tube and a more reliable finished product. In general, square aluminum tubing serves as a cost-effective alternative to steel. As it is available in a broad range of sizes and dimensions, it is suitable for a variety of fabrication applications.

Continental Steel: Your Partner for Every Aluminum Need

Aluminum is a versatile material that offers strength, durability, and other favorable characteristics to a number of industrial applications. At Continental Steel & Tube, we offer aluminum in a variety of forms, as well as other specialty metals such as brass, bronze, nickel, steel, stainless steel, and titanium.

If you’re interested in learning more about our product offerings or leveraging the power and durability of aluminum, contact us today to request a quote.

Aluminum Forms

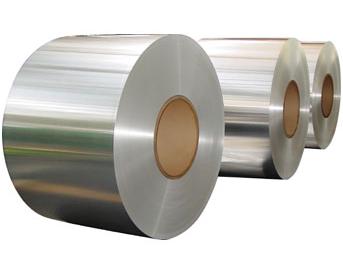

Aluminum Sheet & Coil

- Non Heat Treatable

- Heat Treatable

- Pre-painted

- Pre-anodized

- Special Finishes

Aluminum Pipe

- Seamless Drawn

- Seamless Extruded

- Structural Extruded

Aluminum Tubing

- Seamless Drawn

- Seamless Extruded

- Hollow Bar

- Welded

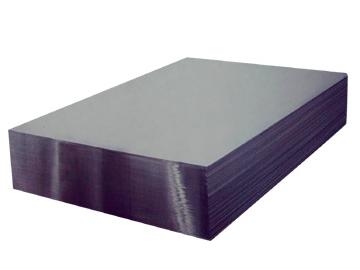

Aluminum Plate

- Heat Treatable

- Cast Tooling Plate

- Diamond Tread

- Precision

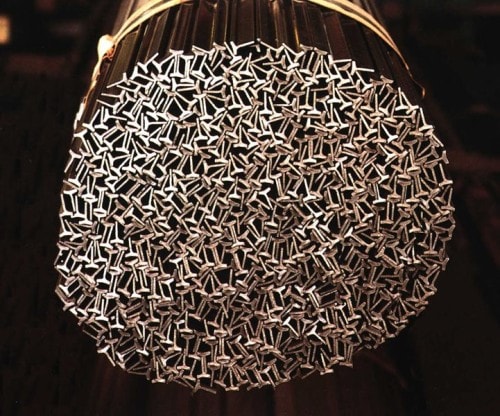

Aluminum Bar Shapes

- Round Screw Machine

- Round Hollow Bar

- Square

- Hexagon

- Rectangle

Special Extrusions

- Email your drawing and prints

Mold Plate

- 6061 Heavy Plate

- ACLA MAX®

- ALUMOLD® I, II, AND IV

- QC-7®

Tooling Sheet and Plate

- ALCA PLUS Cast Plate

- AZ31B Magnesium Tooling Plate

- AZ31B Magnesium Sheet

- MIC 6® Cast Plate